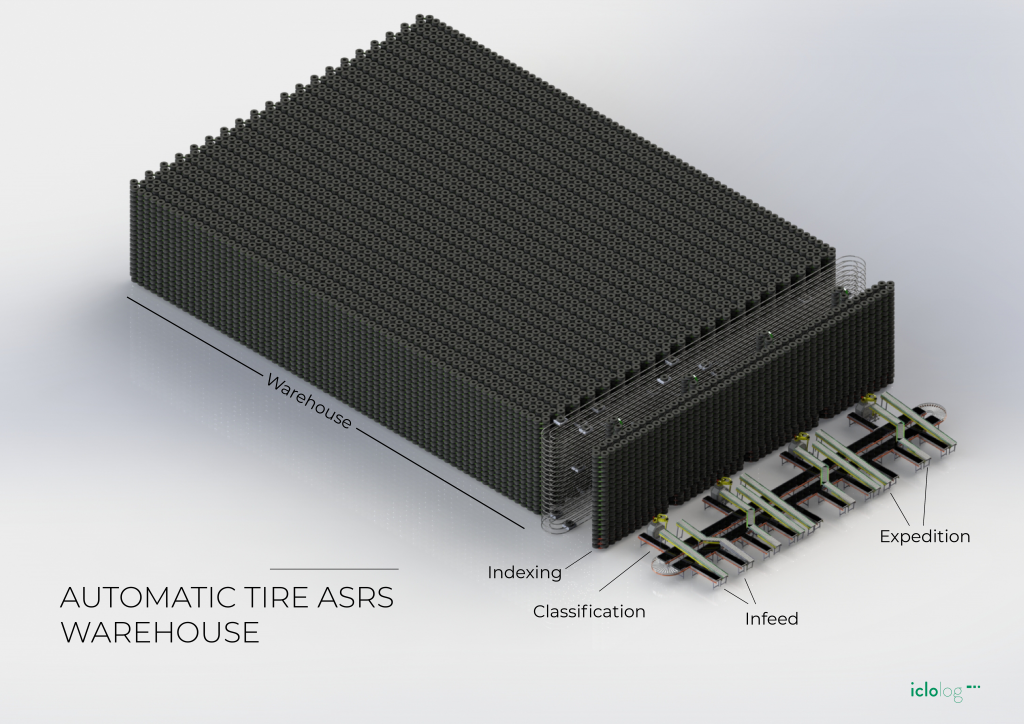

Automatic tire ASRS warehouse

Store tires as unitary loads

Automatic classification by reference

Continuous and simultaneous movement of product

Dynamic flexibility on intralogistics stock movement

This technology is based on overhead chain conveyors, which allow to manage unitary loads and give dynamic flexibility on intralogistics stok movement. The installation includes two different areas:

1. Tire reception and dispatch area, which includes automatic reference reading and batch preparation. This first area includes 4 processes:

Infeed

Reception of the tires and transporting them to the storage.

Classification

On the way of the tire to the warehouse, an automatic code reader is installed to classify and introduce the characteristics of the tire to the system. From this moment on, the position of the tire is tracked until it leaves the warehouse again.

Indexing (batch preparation)

Space reserved for the preparation of the batches to be dispatched, according to customer’s needs. It guarantees maximum speed once the expedition can be made and the truck is in place. It confirms the delivery of the tire to the system once it is made.

Dispatching

Exit of the prepared batches in the indexing zone upon request and in the desired order.

2. The warehouse is the main part of the installation:

Automated warehouse with unit loads and different transport storage lines. It includes dynamic entry and exit of tires allowing different movements simultaneously. It keeps the traceability of each tire, which describes the characteristics of each one.

benefits

Goods-to-person

Unitary loads

Storage surface reduction / increased stock capacity

Time to market:

High productivity

Control Scada

Workforce saving

Elimination of forklifts

Loads and processes safety

Tire rotation system